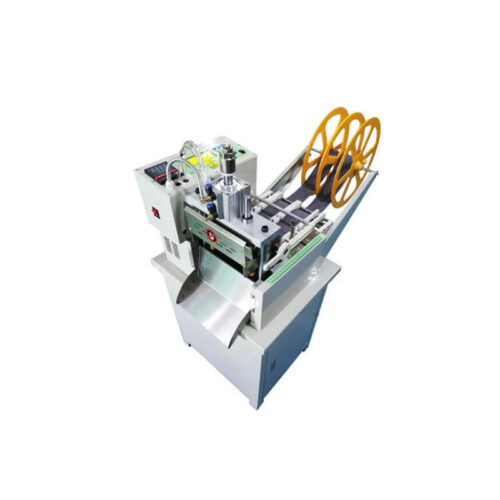

Automatic Webbing Cutting Machine

The webbing cutting machine is an automatic fixed-length cutting equipment specially used for cutting strip materials, such as shoelaces, Velcro, webbing, and elastic bands… It plays an important role in many industries.

I. Diversified Classification

1. According to different materials:

– Cold knife cutting machine: Suitable for temperature-sensitive materials. During the cutting process, it will not generate high temperature and can maintain the original characteristics of the material.

– Hot knife cutting machine: For some specific materials, hot knife cutting can achieve a cleaner cutting effect with neat edges.

2. According to different material thicknesses:

– Light-duty cutting machine: Mainly processes thinner strip materials. It is flexible in operation and has high efficiency.

– Heavy-duty cutting machine: It can easily handle thicker materials. With strong power, it ensures the accuracy of cutting.

3. According to different cutting angles:

– Cross-cutting machine: Realizes rapid cutting in the horizontal direction and is suitable for conventional cutting needs.

– Rotary head cutting machine: It can flexibly adjust the cutting angle to meet cutting requirements at different angles.

II. Powerful Customization Function

While cutting, this equipment can also perform customized processing according to customer needs. For example, rounded corner cutting can make the material edges more rounded, beautiful and not easy to hurt people; bevel cutting can meet specific installation needs; and the punching function provides convenience for subsequent assembly or connection.

In short, with its diversified classification and powerful customization functions, the webbing cutting machine provides an efficient and precise solution for the processing of strip materials.

-

Model Number: GMT-160 Cutting Width: 1-160mm Cutting Length: 1-99999mm Voltage:110V-220V 50Hz Blade Type: Cold Blade/ Hot Blade Max Blade Temperature: 650℃ Machine Size: 550*500*1150mm